Laser cutting for schools and makerspaces: suitable materials and tips

Laser cutting in schools and makerspaces: which materials work well?

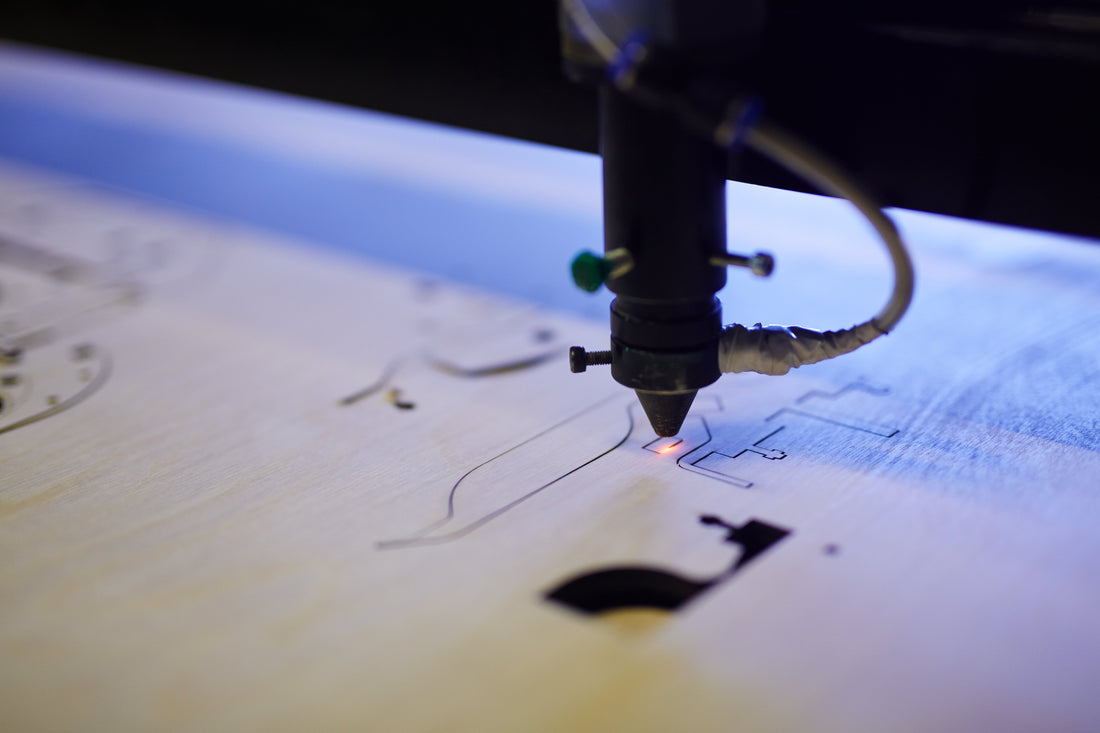

Laser cutting is no longer just for design studios or companies. More and more, laser cutters are found in schools, libraries, and makerspaces. And that's good news: it's an accessible way to introduce students and makers to digital design and creation.

But which materials are suitable for these environments? What is safe, affordable, and practical to use? In this blog, you'll read what to consider and which materials have proven to be the best in practice.

Why laser cutting is valuable for education and maker spaces

Laser cutting combines technology, design, and direct execution.In education or a shared workspace, it helps people to:

- learn to work with CAD software

- gain insight into materials and manufacturability

- make their ideas tangible

- work iteratively: design, test, improve

Whether it's a profile paper, a model, or an art project, laser cutting enables quick and precise work.

What should you consider when choosing materials for schools or shared workspaces?

In learning environments or public makerspaces, it's important that materials:

- are safe to cut (so no PVC or adhesive layers that emit harmful fumes)

- exhibit predictable behavior when cutting

- are affordable for frequent use and experimentation

- are easy to store and use

Additionally, it's convenient if they are laser-ready: flat, clean, and equipped with protective film where necessary.

Four recommended materials

1. Poplar plywood (laser quality)

Poplar plywood is light, affordable, and easy to laser cut. Its fine structure results in minimal splintering, and it has a relatively mild odor during cutting. Suitable for educational materials, model building, constructions, or art projects.

Choose laser quality: these sheets are flatter, cleaner, and specially selected for ease of cutting.

2. Cardboard

Ideal for prototypes, crafts, or architectural models. Cardboard is thin, cuts quickly, and is very budget-friendly. Especially handy for workshops or when working with large groups.

Make sure the cardboard is suitable for laser cutting. Some types of cardboard contain adhesive layers that react poorly to the laser.

3. MDF

MDF cuts cleanly and precisely, and is nicely stable. Think of nameplates, decorative objects, or technical models.

Note: MDF produces relatively much smoke and odor when cutting. Ensure good ventilation.

4. Acrylic (PMMA)

Acrylic gives a professional appearance and is good for engraving. Available in clear, matte, or colored.Very suitable for end products such as awards, displays, or personalized objects.

Only use PMMA – no PVC or polycarbonate – and ensure adequate ventilation during cutting.

Practical tips for safe and efficient use

- Use only materials suitable for laser cutting

- Store materials flat and dry to prevent warping

- Test settings with each new material or thickness

- Ensure good extraction and ventilation

- Keep leftover pieces – ideal for tests or small projects

Conclusion

With the right materials, laser cutting becomes accessible, safe, and effective – even in learning environments and shared workshops. Start simple, let users discover for themselves, and invest in materials that work predictably and pleasantly.

Laser Cut Supply offers a carefully curated selection of laser-ready materials, specially suited for education and makerspaces. Available directly from stock, neatly packaged and tested for cutting ease.